Synthetic and glass fibres have never completely substituted natural fibres. On the contrary, there is a growing interest for application of natural fibres in composite materials – biobased or not, biodegradable or not – and as an insulating construction material. Natural fibres have one third less weight than glass fibres, and have other advantages on top of that.

Biomimicry

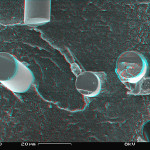

There is a large variety of natural fibres. There are mineral fibres (asbestos), but they are not of particular interest to us. Many fibres are vegetal in origin, like cotton, hemp, flax, jute, coir, abaca, and sisal. From times immemorial mankind has used them for clothing, and also for polymer reinforcement, from the time onwards that these were introduced on the market. Wood, the construction material, is applied in increasing quantities as a reinforcing agent in composite materials as well. Cellulosic fibres have always been the feedstock for paper production, about the oldest biobased activity. Animal fibres like cobweb, silk, wool, catgut, alpaca, camel hair, kashmir and mohair are mainly used for clothes production, although there is a renewed interest for the opportunities of cobweb and other materials – not made by spiders but by bacteria – for bulletproof vests. We call it biomimicry.

Why did glass fibres ever threaten to take over natural fibres in materials production and the construction trade? They were cheaper, but were they better as well? Natural fibres have always found applications: sisal in ropes, and cotton, flax and wool in clothing and other textiles. Wood still is the most important construction material. But the major fossil polymers took over most of the market share of vegetal and animal fibres in ropes, clothing and other products, not unlike the substitution of natural fibres by glass in construction materials reinforcement.

Lighter materials, lower energy use

Now however, natural fibres are in the middle of a major revival, inspired by designers and architects with a keen eye for ‘green’. Natural fibres prove to be excellent reinforcing agents. Some sources even report that natural fibres supersede glass fibres. Because they are lighter, as a result of which the construction elements (like car doors) become lighter as well. Up to 30% lighter. Important characteristics in the transport sector, because lighter construction elements save energy use. Moreover, their production requires less energy, and less chemical binding agents that glue them to the resin. They incur the ultimate benefit when used in combination with biodegradable polymers, like Wood Biopolymer Composites. If both constituting elements are biodegradable, they may be composted after use. All other reinforced composite materials pose problems in reuse and recycling because of the mutual bonding. Glass fibre reinforced composites cannot even be used for energy recovery, as the constituting elements cannot be separated – and glass will clog the hearth with its melt. And more good news: composites containing natural fibres and biobased resins produce much less pollution (up to 80%) than their counterparts containing glass fibres and fossil based polymers; and their production costs appear to be competitive already.

But as yet, there are only few companies that produce these materials. A Dutch company constructed a catamaran using a composite material reinforced with natural fibres that successfully sailed for some years now, and road markers used in natural areas. The company inspires (young) designers in designing and producing new appliances, and architects to design buildings with façade plates using natural fibres. The green building and construction community has high hopes of the combination of biodegradable polymers and natural fibres in particular.