Just a few years ago, bio aromatics seemed far away. Aromatic compounds could be so easily extracted from (fossil-based) naphtha, that bio aromatics seemed to be a dream for the future. Primarily because the most probable resource, lignin, is hard to handle. But in this field, as in many branches of green chemistry, knowledge advances so fast that research groups like the Dutch/Flemish Biorizon (TNO, VITO and Green Chemistry Campus) foresee the possibility of commercial production of bio aromatics from lignin in less than ten years’ time.

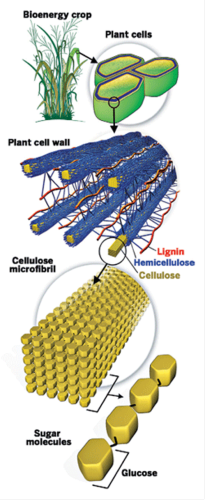

Lignin is abundantly present in wood, where its acts as a kind of glue that binds together the strains of cellulose and hemicellulose. Its structure is very complex, a three-dimensional conglomerate of various aromatic components tightly linked together. Present chemical know-how is not sufficient to separate lignin into these components. Moreover, the lignin on the market now is a side product of the well-developed Kraft process for paper production, and it contains too much sulphur for subsequent successful processing due to catalyst inhibition. But, as Ludo Diels (Biorizon) pointed out at a workshop last EFIB, there are new processes towards producing bio aromatics from lignin, that could develop fast in the years to come.

Four pathways towards bio aromatics

The first pathway is to feed lignin (after de-oxygenation) to a cracker, where it has properties comparable to crude oil and will produce a kind of naphtha, containing a variety of aromatic compounds. This process is nearly operational today, although its cost-effectiveness is very much dependent on crude oil prices. The second pathway is to produce BTX (benzene, toluene, xylene) catalytically from biomass or lignin in one step. This process is still in development, among others by the Dutch company BioBTX. But Biorizon is primarily involved in the third and fourth pathways. In the third pathway, bio aromatics are produced from sugars by the Diels-Alder reaction. This is where Avantium comes in. This company concentrates on the commercialisation of furan and its derivatives. (Furan is an aromatic hydrocarbon in which the ring structure contains four carbon atoms and one oxygen atom; it and its derivatives can easily be produced from sugars). With the Diels-Alder reaction, aromatic compounds can easily be produced from furan derivatives. For instance, dimethylfuran will produce p-xylene when treated with ethylene. This is a direct route to bio aromatics from sugars, that are increasingly available at low prices in the market.

2019 is just around the corner

The fourth pathway, finally, will produce bio aromatics directly from lignin. A first achievement in this step is that finally, researchers have succeeded to produce a reproducible quality of pure lignin that can be used as a benchmark. In this fourth step, lignin will be hydrolysed, followed by isolating the components by nanofiltration or pervaporation. Separation technology, using ceramic or polymer membranes as developed by VITO, is essential. This step will produce phenolics, oligomeric phenols and polymers, that can subsequently be processed to fine chemicals, fuels, lubricants and more, with bitumen as a rest product. A the present speed of developments, we might witness the first pilot plants processing lignin to bio aromatics in 2019, Biorizon estimates. In collaboration with KU Leuven they develop a direct catalytic wood attack leading to an efficient way to alkyl phenols and sugar polymers.

The discussion at the workshop was mainly about the consequences for a European feedstock strategy. In a bioeconomy, chemical industry will need a variety of resources for a solid feedstock position. It cannot rely on just one crop. Across Europe, people stated, we will need a balanced input of first and second generation crops. If the gap between aliphatic and aromatic chemicals can be bridged as easily by the Diels-Alder reaction as suggested, this will greatly enhance the flexibility of resources for the chemical industry. In the minds of bioeconomy policy makers, 2019 is just around the corner. New molecules, highly functionalized, and with new characteristics leading to better performing polymers and materials, raise the highest hopes.