The production of levulinic acid is gaining momentum. Levulinic acid is one of the chemicals on the famous list of green ‘chemical building blocks’ of the US Department of Energy, some ten years ago. Chemical industry is organised around the production and further processing of such building blocks or ‘platform chemicals’; in the biobased chemical industry, these will differ from the present chemicals, dictated by petrochemical logic. The first new building blocks to be developed were furans (Avantium) and succinic acid (BioAmber, Reverdia); that levulinic acid now follows, indicates that the biobased economy gathers strength.

Levulinic acid: small volumes, as yet

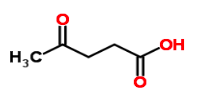

Levulinic acid, or 4-oxopentanoic acid, is produced from by-products of the sugar industry. It is the precursor to a large number of products, including pharmaceuticals, agrochemicals, flavours and fragrances, personal care products, food additives, resins and coatings, plasticisers, solvents, fuel additives and biofuels. So far, levulinic acid was available on the market, but in insufficient quantities and produced by a process that had trouble to meet environmental standards. Two companies recently announced however that they have developed a new pathway, apparently using fermentation technology, with much less environmental impact and with the prospect of delivering the product at a lower price. The first is GFBiochemicals, a company that at present concentrates on this very chemical; it is constructing a 2 kton/year production facility in Caserta, Italy, that is set to come online mid-2015. The company has been operating its technology at demonstration scale since 2008 and it intends to scale up to 8 kton/year by 2017. Its competitor is Bio-On, also an Italian company. Its technology is commercially less developed, the company recently announced that Eridania Sadam, an Italian agro-industrial group, will invest € 1.8 million in the development of its levulinic acid production technology.

To be sure, so far these volumes are small in the international industrial context, about 100 times as small as many petrochemical facilities. But Lux Research Inc., a US consultancy firm, takes these announcements as indications that ‘the levulinic acid space is gaining momentum’. It draws a parallel with the somewhat related molecule of succinic acid. Both can serve as a stepping stone for the production of many products, ranging from personal care products to plastics. ‘Despite its small size,’ Lux Research writes, ‘we have seen demand grow within the succinic acid space, given the broad downstream potential it offers for producers. Demand is likely to increase within the levulinic acid space also, given the opportunities it provides as a building block chemical.’ And it foresees the development of a new value chain based on this building block.

A bridge between the agri and chemical industries

‘GFBiochemicals specialises in the research, development and production of biobased chemicals and fuels,’ says its website. ‘Our products offer a sustainable alternative to traditional fossil-based materials. These products are not only better for the environment, by reducing and preventing pollution at its source, but also safer for users and consumers.’ Their levulinic acid technology, says the company, offers great opportunities: high conversion yields that improve efficiency, while reducing waste and cost; and synthetic versatility that allows for the production of valuable derivatives.

Bio-On is a company that develops sustainable chemicals, bioplastics and bio-fermentation technology. It already produces PHAs (polyhydroxyalkanoates, biodegradable plastics) from agricultural waste like molasses. The agreement with Eridania Sadam for its levulinic acid technology is particularly interesting because this company is in the sugar sector, thus building a bridge between the agri and chemical industries; and precisely this will form the backbone of the biobased economy.

In short, although volumes are small as yet, levulinic acid has the seeds in it for further development of the biobased economy.

Interesting? Then also read:

Biobased materials and chemicals driven by performance

The case for new biobased platform chemicals

PHA: promising, versatile, biodegradable

Een zeer informatief geschreven artikel. Ons bedrijf Agernomics BioTech BV heeft een proces ontwikkeld waarbij wij Levulinic zuur produceren gebaseerd op onze speciaal ontwikkelde napier plant varieteit BioVoltz. Wij zouden graag in kontakt komen met afnemers van ons produkt.