Green chemistry is not just another science than the existing, fossil-based chemistry; green chemistry represents another philosophy as well. Whereas chemical industry now tries to synthesise complex substances from simple building bricks, green industry will start from the chemical complexity of the feedstock and try to keep this intact throughout the process or even use it as such. We will move from reductionism to holism: towards processing the entire resource as such. This is a revolution in chemical philosophy.

This is the third article in a series on green chemistry. The articles appeared on 5 June, 14 June, 19 June and 12 July 2015.

The first steps

Previously, Alle Bruggink and Johan Sanders made a plea on this site for preservation of chemical complexity in industry. We now take as an example green construction materials, like green composites. These have applications already in car interior panels. Composites are materials of different properties, intricately linked together in order to achieve special properties like strength combined with light weight. Industrial composites consist of a plastic (typically a polyester) reinforced with a fibre. Entirely green composites consist of green plastics, reinforced with cellulosic fibres. At present, production of such green composites still follows existing chemical logic: synthesis from simple building blocks. Typically, the biobased resource will be sugar, feedstock for the fermentation of succinic acid and butanediol; these being the building blocks of the biobased polyester PBS. And then we can reinforce this with fibres derived from wood or straw. Very slowly, against all odds of strict price and quality requirements, such green panels gain ground in the motor car industry. We can regard the injection with natural fibres as a first cautious step towards preservation of chemical complexity.

Holistic start

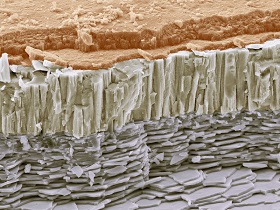

Green chemistry will approach the construction of ‘green’ car panels in a radically different way. Nature supplies us abundantly with an excellent construction material: wood, itself a composite. But wood does not fulfil motor car industry’s requirements. Even though luxury models are adorned with smoothly polished expensive wooden panels, done with much manual work. Existing wood products like plywood do not meet the standards for mass production of panels: not flexible, too vulnerable etc. But researchers increasingly unravel the mysteries of the structure of wood, and learn how to manipulate these with micro interventions. We can already confer the properties of hardwood to softwood by coarse interventions like heating or treatment with acetic acid anhydride. Researchers have also succeeded in dissecting cellulose fibres to fibrils and these to micro fibrils; from these they can construct materials with any desired property, like beams stronger than steel or fibres with the properties of cotton. So we can imagine that in the future we will be able to produce a panel directly from the tree. All we have to do, so to speak, is selecting the proper kind of wood, and applying the proper enzymes, chemicals and temperature treatments at the right places. Looking further into the future, we will be able to improve many production processes by preservation of chemical complexity, and even discover many new ones.

New opportunities by preserving chemical complexity

Starch and proteins are other vegetable compounds, in ample supply, that we learn to use in their natural makeup, after mild treatments. A fine example of preservation of chemical complexity are starch plastics – directly produced from starch without breaking it down to its components. Their unique properties allow starch plastics, developed less than two decades ago, to be used in special applications, like biodegradable plant pots that the horticulturalist can leave in the ground. With proteins, properties even depend much more on structure. In most cases, processing proteins, for example to animal feed, still starts nowadays with breaking up that structure (denaturation, like on boiling an egg). But potato processor AVEBE developed a process in which potato proteins are isolated in their original structures (hence retaining their biological activities). With some fantasy, we can foresee many new applications of this technology. AVEBE’s proteins now still find their ways to fairly simple products, like sports drinks and whipped cream. But if researchers could extend this process to other plant species, isolation of a vast array of medicinal and otherwise useful proteins would come in sight. Not to mention the taste effects that could result from the use of fully functional vegetable proteins.

Assistance from biology

Synthetic biology might teach us a new look on our treatment of chemical complexity. So far, most synthetic biologists just turn the knobs of genetic codes, manipulating the end products of the metabolic pathways. But working together with chemists, particularly those developing catalysts, they increasingly learn how to unravel the individual steps on the metabolic pathway, and determine which genetic codes (together with all subsequent steps) command these reactions. That leads to the discovery of new enzymes or to the design of new catalysts that allow us to perform subtly and purposely one single reaction in a complex structure. Not perchance the number of projects and proposals on catalytic processing of biomass exceeds all expectations right now. And in an increasing number of projects, the aim is not just to break down complex molecules to simple building blocks (the so-called biofuels or monomers for bioplastics), but hands-on and direct processing of the resource into complex products.

In his column, Alle Bruggink draws a parallel to farmers and cooks. Both know perfectly well how to enhance the quality of their products – but so far, science just did not fathom which chemical reactions determine those manipulations. Researchers will discover them, bit by bit. In doing so, they themselves will become more like farmers and cooks in course of time – understanding what they do, producing special quality and taste effects. Preservation of chemical complexity is going to open up new worlds.