The contours of the future energy system haven’t yet been drawn with great precision. Solar and wind energies lie at its foundation. But these come with their problems: at times they produce too much, at times too little energy. We need energy storage, in order to use the excess and to bridge periods of low supply. A new option for such an energy storage: iron powder. An option that comes with its strong and it weak points.

The fundamentals

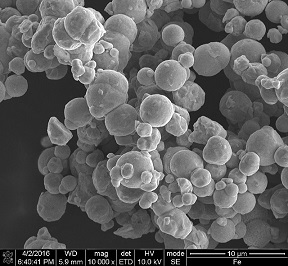

Iron powder reacts with oxygen to form iron oxide, rust: 4 Fe + 3 O2 à 2 Fe2O3. Producing a lot of heat. To such an extent that in terms of volume, heat production almost equals that of burning natural gas and gasoline. And in terms of weight, iron is much better than lithium-ion batteries. Metal powder and air are injected into a burner, where incineration takes place. The rust produced will be separated from the hot air in a cyclone and caught in a storage tank. We can use the very hot air in industrial processes, for production of electricity or residential heat, or for propulsion of machines or vehicles.

The use of iron powder as an energy storage medium is now under development at RIFT (Renewable Iron Fuel Technology), a spin-off of TU/e (Eindhoven Technical University). The process will produce rust, that we can restore to form iron powder again. That’s ‘reloading the powder’. In other words, iron powder is a circular fuel. We store energy in iron and use that when we incinerate it; and we then recover the iron in the ‘reloading’ process.

Iron powder in the energy transition

Mark Verhagen, RIFT’s CEO, says to the site of TU/e that iron fuel will contribute to a more sustainable energy supply. ‘For industrial processes and district heating, we need lots of energy. Sustainable options like electricity and hydrogen will not be able to supply that at all times and places. Therefore, in these sectors alternatives like iron powder are very important,’ he says. And Philip de Goey, professor in incineration technology, calls iron powder ‘one of the most promising solutions for the energy transition, as we can easily and safely transport it, and store it in major quantities.’

The technology has now been developed to such a level that RIFT built a test site of 1 MW. A test boiler that burns the iron powder, in Helmond near Eindhoven. And an installation that reduces the rust powder back to iron, in Arnhem. Together with a local heat supplier, RIFT will heat 500 homes with iron fuel.

Iron powder’s advantages

RIFT originated as a start-up from SOLID, a student team at TU/e. Their first test of the system was at the brewery of Bavaria beer in the factory of the Swinkels family. According to Verhagen, student teams are important instruments in the development of new technologies like iron fuel. And as the CEO of RIFT, he is glad to complement those enthusiasts with older technicians with a lot of experience.

The main advantage of the use of iron powder as a fuel is of course that it will not produce any CO2 in the process of heat production. But iron is just the storage medium of energy – and therefore it is decisive how the rest of the cycle looks like. Both in terms of energy efficiency and CO2 production, and in financial returns. In those fields, there are large differences of opinion. We need to look closer into those areas in order to decide what’s true.

Of course, we should firstly make the right choice for the process that will regenerate iron from rust. We cannot use carbon in that process, like in a blast furnace, for that will produce CO2. We should regenerate with sustainably produced hydrogen. Not produced in the reaction CO + H2O à CO2 + H2, but by electrolysis of water, using sustainably sourced electricity. This reduction with iron ore by hydrogen is in tune with a movement within the iron industry. In order to reduce their CO2 emissions, Tata Steel in IJmuiden (the Netherlands) decided to use hydrogen, instead of reverting to CCS first. Thyssenkrupp in Germany and SAB in Sweden also plan to move into that direction.

Iron as a form of stored hydrogen

We can look upon hydrogen as the intermediate compound. But equally, we could look upon iron as a form of stored hydrogen. Albeit heavier, but then, also much easier to handle. Even though such an intermediate step implies that this process will have to compete with the direct use of hydrogen (in terms of energy efficiency and of financial returns). And as for energy efficiency, the process has many more competitors. In the storage of solar and wind power for instance, it needs to compete with load management, batteries and pumped accumulation storage. In the delivery of CO2-free heat, direct use of electricity will be the main competitor.

Moreover, the process of using iron powder is by no means in the bag, from a technical point of view. We will have to blow the powder into the furnace with great precision, in order to ensure full incineration. The large volume of rust that is produced in the process, causes problems of its own. Like erosion of the equipment by solid iron and rust particles.

The cycle

And then, there is the major question: where will we regenerate the rust? We could do so in sunny areas around the equator. We can use existing infrastructure for that process. To that end, we reconstruct oil tankers to iron carriers. We do need to take care to transport the iron in a protective atmosphere, in order to prevent it from turning into rust prematurely. But his cycle too has its competitors, like the use of ammonia, methanol and hydrogen (once more) as energy carriers. These can be produced on the spot and do not have to be transported to sunny countries for regeneration.

One last question: how do we source the iron itself? The present process of producing iron releases a lot of CO2. Because iron ore reacts with carbon monoxide: Fe2O3 + 3 CO à 2 Fe + 3 CO2. We will have to start producing iron sustainably in the first place, using sustainably produced hydrogen: Fe2O3 + 3 H2 à 2 Fe + 3 H2O. And finally, we will have to sinter the iron in order to produce iron powder. Another process that requires energy and funding. In short, we have not by far developed the technological pathway toward the iron cycle yet. And then, this pathway will have to prove itself, in competition with the alternatives for storing energy.

Hoe viable is iron powder as a fuel?

For these reasons, a discussion has been waged on the internet as to the viability of this process. What is the overall efficiency of heat production using iron powder as an intermediate? Hydrogen production from water by electrolysis already comes with its inefficiency, the efficiency being about 75%. The total cycle of iron incineration plus regeneration might then attain an efficiency of 65%. The efficiency of process heat production from iron incineration might be 85-90%. The entire cycle, as now in place at Bavaria, might then attain 55-59% at most. Will that do? And for which applications?

In two years’ time, RIFT intends to construct a 5 MW device for the use of iron as a fuel. They already signed a letter of intent with Veolia industrial services. Verhagen: ‘I envisage a future for iron fuel, alongside with wind turbines, solar panels and hydrogen, as an important sustainable alternative to fossil fuels. Our goal is that we will be able to decarbonize industry worldwide, using iron as a fuel.’

Interesting? Then also read:

Cheap energy storage speeds up

Energy storage, its role in the transition

Energy policy: don’t just choose low-carbon – create a new energy system