This week, World Bio Market Insights ran an interesting article about bioeconomy and circularity. These are both required for building sustainability into value chains; but they are not identical. Both need to be addressed.

Biobased and circularity

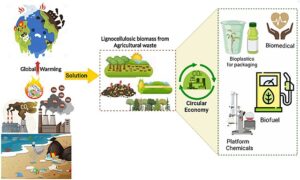

Biobased materials stem from biological growth. Examples are wood, algae or crustaceans. But often, biobased materials aren’t circular. Circular materials are made from waste byproducts; or they are made from repurposing an older product that has reached the end of its lifetime. Circularity turns an old product of byproduct into a new and valuable one. We need circularity because it reduces the need for mining (and its energy use); and because it cuts the amount of products going to landfill.

Bioeconomy and circularity are different but can go together. World Bio Market Insights gives the example of a compostable packaging material, made from agricultural wastes. Here it is important that it is made of wastes – for then, it needs no additional inputs. The product could even be more sustainable if it would release plant nutrients when degrading. But of course, this would presuppose a waste system where biodegradable products will be returned to the land.

Sustainability

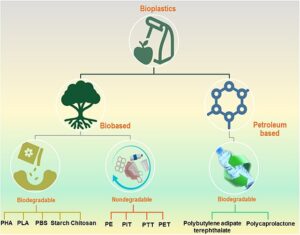

A biobased material is not circular by itself, it can even be environmentally damaging. For instance if its production releases greenhouse gases. Or if the product cannot be recycled after its useful lifetime. For in this case, we need to spend the energy and resources required for making the product, over and over again. But of course this would be different if the product would be produced from waste. Then we would only have to spend some fresh energy and raw materials.

Therefore, biobased does not equate sustainable. In order to grow plants and trees, we need land and resources. Non-circular biobased can turn into landfill fodder just like any other product. Many biobased plastics for instance are indistinguishable from petrochemical plastics.

Circularity

One of the main proponents of circularity is the European Union. In 2015 it published its action plan Closing the Loop: The EU Action Plan for the Circular Economy. One of its reasons is the need to reach climate goals. Even where biobased materials are concerned. One of the EU’s bioeconomy funding bodies is called the Circular Bio-based Europe Joint Undertaking (CBE JU). One of its projects is called SYMBA, aiming to generate ideas for how to create regional zero-waste value chains that efficiently combine circularity with renewability. One of the driving forces is a security strategy, fuelled among others by the sharp reduction of Russian natural gas imports. SYMBA aims ‘to make supply chains tighter, more localised, and less vulnerable to disruption by foreign entities’.

Cascading is the method to use biomass as circularly as possible. Biomass should go to the highest value industry possible, each time it is used. The purpose of cascading is to make the most efficient use possible of finite biomass resources; and to avoid burning it for energy, as long as possible. Incineration is only the final step in a cascade of uses; it should be avoided to the maximum.

Towards a market for biobased materials

One of the companies active in this field is Circular Investment. It specializes in supplying circular biobased raw materials. Like ‘forestry byproducts from hardwood or softwood species; organic byproducts like proteins, sugars, and starches from horticulture and agriculture; and non-biobased waste byproducts from the construction industry.’

Nevertheless, it is hard to build a market for biobased materials. Supply chains still have to be formed. And the branch would profit much from regulation, for example creating market demand for circular biobased goods. This would attract investors and suppliers in this segment, and get circular biobased resources off the ground.

Interesting? Then also read:

Circular bioeconomy: an uneasy marriage of concepts, so far

Sustainable biomass: a subject fraught with conflict

Carbon capture and utilization (CCU)