In a circular economy, we will use as few resources possible. These we will reuse again and again; in so doing, we will postpone mining new resources as long as possible, we might even prevent this from happening. The Netherlands have formulated the goal to be entirely circular by 2050. But this is a far-stretched goal. Globally, less than 9% of the economy is circular. Utrecht University’s Marta Jiménez listed the results and dilemmas (links in Dutch).

Unsustainable practices

Just an example. The production of a plastic water bottle requires three times as much water as it will contain; and enough fossil oil to fill one quarter of the bottle. And then, the bottle will travel as much as 15,000 km before we can take hold of it. And probably, the bottle will not be recycled. It will end up in the bin, and in the most positive case, it will be burned.

For many years now, we discuss world-wide the restriction of global temperature rise to 1.5oC. But reality is different. A circular economy isn’t ecologically sustainable, says Kieran Campbell-Johnston. Each year, we use more instead of less resources. Reuse isn’t well-developed. If we continue to act along this path, we could end up with a global temperature rise of 3 to 6 degrees. Why don’t we act differently? For instance, by filling up again used bottles – instead of buying new ones? But there is a fly in the ointment. For if we remake glass bottles, this will require much more energy than we will need for plastic throw-away bottles. Therefore, a circular economy isn’t by definition better than a once-through economy. And if we act in a circular way, we need to know that the result that the result is sustainable.

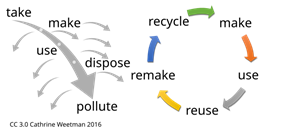

Circular economy: what is it?

But then, what is a circular economy? Another subject of research by Utrecht researchers. ‘We should be able to construct just what we can also demolish’ says researcher Denise Reike. ‘We should only call an innovation circular if there is a clear plan in sustainability and long-term use, and just if we can store the chemical components, or allow these to be reused in nature.’ And in order to determine that, we need research.

An example of a sustainability is the production of wrapping materials from moulds. This is the area of research of microbiologist Han Wösten. ‘Moulds can transform low-value agricultural waste like corn stalks into high-value materials. It is a fascinating material,’ he says. The mould structures were a source of inspiration for artists and designers; they turned the material into bricks and light-weight chairs, even self-repairing dresses. And sustainable materials like wood, cork, leather, plastic and rubber. Packaging on the basis of moulds has one big advantage. After use, it can be discarded into the garden; there, it will break down in a matter of weeks.

Reusable and reused

Reuse is a potentially successful strategy in the circular economy. Researcher Patricia Megale Coelho mentions as an example glass beer bottles – reused in Europe thirty times on average, sometimes even fifty times. This reuse compensates for the much lower environmental impact of the production of a plastic bottle. In an effective reuse system, the collection, cleaning, filling up and returning it to the production line is less environmentally damaging – if this will happen at least five times. It would even be better if a number of brands or companies would make use of the same reusable packaging. Meaning: if we could return a reusable packaging to many locations (for reuse) – not just bottles but also plastic trays.

But sometimes, collecting materials for reuse isn’t very simple. Computers and telephones for instance can contain hundreds of different materials. ‘Separating them is extremely difficult, then,’ says chemist Alex van Silfhout. A major part of our electronic waste is now illegally shipped to Africa. Where it will be downcycled; or it will end up in the dump.

Electronic waste

Van Silfhout developed a magnetic fluid that might be of assistance in the circular economy. In one single step, he recovers for reuse all those valuable, often scarce, particles from the huge pile of electronic waste. The principle of the operation is fairly simple. Materials of different specific weights will float on different levels in the magnetic fluid. For instance, lead and cadmium are heavy. A strong magnet will have the effect that different materials will float at different levels in the fluid.

But we will have to prove whether this can serve as an effective means of recycling e-waste. ‘We will need much more magnetic fluid and a stronger magnet. Both are costly, although the principle will remain the same.’ But in principle we will be able to recycle discarded electronics and the valuable resources contained in then.

Towards chemical recycling

The mere fact that recycling can be done, isn’t sufficient for the circular economy. We used to think that the mere offer of plastic, glass and paper waste would be sufficient for a second life of the product. But in actual practice, only a small portion of the plastic collected in this way will end up in new products. ‘Less than 10% of all plastic ever produced has been recycled,’ says chemist Ina Vollmer. Plastic products are being refined for use all the time – not for recycling. Just a few kinds of plastic can be easily recycled, like PET and HDPE. But even then, only if they are being sorted and cleaned well. Most plastic packaging just isn’t tuned to our system of collection and recycling.

The problem is that we use many different kinds of plastic in the same kind of packaging. Therefore, separating them and reusing them in a new plastic product is rendered difficult. All the more so if the packaging is contaminated with food, and with materials like aluminium and paper – then we cannot recycle the material using present-day technology, says Ina Vollmer. That’s why she concentrates on chemical recycling. Through that technology, we can even recover and reuse difficult kinds of plastic.

In plastic recycling, as we tend to use it, quality is being downgraded fast – all the more so if the plastic isn’t pure, and mixed with other kinds of plastic. But Vollmer’s subject is chemical recycling. In this procedure, polymers are being broken down to their original building blocks. In a circular economy, we can reuse them for the production of new plastic materials. Which will prevent old plastic to end up in nature; and which will reduce our dependency on crude oil.

Towards circular strategies

But it is still a far cry from strategies for a circular economy. In this, we would return plastics to the original materials, and start making plastics from there again. Walter Vermeulen researches the financial and policy measures, required for such a strategy. In the Netherlands, glass and paper are being collected more than formerly, but not yet plastic – at any rate, not in a useful form. Possibly, we should use the so-called Extended Producer’s Responsibility in order to achieve that. Now, sustainable alternatives tend to bee too costly. But we might reward sustainable pioneers with sizeable rebates. Or strengthen rules to such an extent that less circular options become less attractive. Charge the non-sustainable alternative.

The object of all this is to achieve 50% circularity in 2030, and 100% circularity in 2050. Using the power of chemistry to promote circular solutions. Towards a circular and sustainable future.

Interesting? Then also read:

Bioeconomy, circular and small scale. Really?

Circular economy: bio-plastics have an issue

Circular economy: do not merely close the chain, but slow it down as well