Biobased resources and biochemical processes will change the appearance of chemical industry. Changes may occur in scale and in location. There will be a tendency towards a smaller scale. But know-how, the skill of process operators, might become an important location factor.

A regional basis

The logistics of biobased feedstock differs widely from that of fossil fuels. Therefore, pre-treatment of the crop to yield a stable and tradable intermediate product, will always take place in the neighbourhood of the feedstock producer, the farmer. We can define ‘in the neighbourhood’ as being within a radius of 50-100 kms. That would lend a regional basis to the biobased economy.

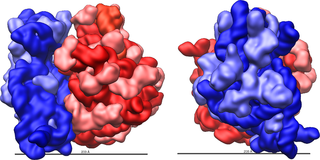

Further processing of the intermediate product, e.g. starch or sugar, to an end product would follow entirely different laws. If the intermediate product would be fermented, the availability of competent and experienced operators might turn out to be one of the most important factors in location decisions. Fermentation is a very vulnerable process; many industrial organisms (bacteria, fungi, yeasts) are not very stable, and very sensitive to competing organisms in the reaction mixture, or to pockets with a different temperature or acidity in the reaction vessel. At the same time, this vulnerability will define an upper limit to the scale of the installation, because reaction conditions cannot be controlled perfectly in vessels that are too large. For many processes, 100-200 m3 would turn out to be the upper limit.

Organism productivity and stability

Generally, a smoothly running industrial fermentation process would further require: sufficient water (as a cooling agent and as the solvent), and a rather low ambient temperature (as otherwise, the process would require too much cooling). Surprisingly, temperate climates would be favourable here, also because in these climates, reaction mixtures will be less susceptible to contagion.

Further development of biotechnological and processing knowledge could further reduce the size of installations. The size of industrial plants will primarily be dependent on organism productivity and on reprocessing efficiency. For modern medicines produced by fermentation, we sometimes have to accept a product concentration of less than a few percent. For some established fermentation processes, it often took decades to arrive at commercially attractive product concentrations of 10 to 20% or more. Better productivity may result in a smaller reactor vessel! Whereas increasing stability in turn might result in a larger reactor vessel, because more stable organisms are less susceptible to contagion or slightly varying conditions. Genetic modification of bacteria, fungi and yeasts is an important tool for enhancing both productivity and stability; biotechnological companies will prefer locations at which they can do this kind of research without much ado. Synthetic biology is a specialism that is going to play an important role in this development.

Trained personnel

But the size of individual installations may not even be an important issue for questions about the scale of a future green chemical sector primarily dependent on fermentation processes. The decisive factor in the choice of location might be the aforementioned availability of competent and well-trained personnel. Fermentation processes are in a higher league of difficulty than classical chemical processes; operators with sufficient know-how might make the difference between a good result and an utter failure. It would be wise for the further development of the biobased economy to turn ourselves to education and training of such operators. Competent operators attract factories; and these in turn train competent operators. The location of future hubs will be decided by the availability of know-how, not by physical infrastructure, and not merely by scientific R&D.

The author thanks Hans van Leeuwen (Bioprocess Pilot Facility in Delft) and Alle Bruggink (former R&D director Corporate Research Life Science Products DSM) for their input