Ludo Diels, senior researcher sustainable chemistry at Vito, the Flemish institute for research of sustainable technologies, is very positive about the future of lignin. This third major wood component (after cellulose and hemicellulose) used to be a waste product, useful at most for energy production; now, research institutes and companies develop many applications.

Three R&D programs

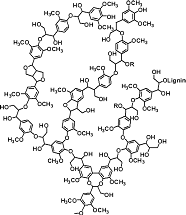

The Flemish/Dutch joint research organisation Biorizon in which Vito participates, has biobased aromatic compounds as its research focus. The first R&D program, says Diels, concentrates on the development of applications for lignin and its hydrolysis products. Nowadays, high-quality lignin is used among others as a structure enhancing agent in concrete; it is blended in polymers, and there is even a possibility that lignin could be developed to a high-tech fibre. But lignin can also be decomposed (depolymerised). Lignin consists of a very intricate structure made up of aromatic molecules (they each contain a phenolic group based on a benzene ring); each of these molecules contains one or more hydroxyl groups and one or more carbonic acid groups, with which they interlink, forming a three-dimensional structure. We now can open up this structure, which produces a complex mixture of partly or entirely depolymerised aromatic molecules: oligomers and monomers. To the cooperation in Biorizon, Vito particularly contributed its membrane separation technology for this mixture.

A second line of R&D consists of the synthesis of aromatic molecules from sugars with furans as an intermediate, through the Diels-Alder reaction. In principle, this path is more costly, but it has the great advantage that researchers can determine with great precision the nature of the final product. In Biorizon, this line of research is investigated primarily by the Dutch, among which TNO and Avantium. The two lines of research produce different kinds of products; lignin processing leads to many new molecules, most of which have no large-scale application in chemical industry yet, whereas the main products from sugars are drop-ins, directly useable in present production equipment.

A third, increasingly important line of R&D consists of pyrolysis of organic material using appropriate catalysts; this produces BTX, a mixture of benzene, toluene and xylene. BTX is a well-known commodity in chemical industry, and this greatly enhances the short-term opportunities for this biobased BTX. The downside is that this process removes all functionality from the feedstock molecules (which also causes an appreciable loss in terms of weight), but it appears to be easier. Many companies are in search of biobased feedstock – and biobased BTX exactly fulfils that need without any requirement of changing the reaction path or the equipment.

Market pull

‘It is of major importance that many companies are now looking for feedstock with a lower ecological footprint or with less health damage,’ says Diels. ‘The new European REACH regulation, that sees upon toxicity and ecological impact, plays a role in this. We will need to give this a lot more consideration. In our work we find a demand for testing materials that lend themselves to test their health impact. Industry asks for compounds with anti-oxidant or UV-resistant properties; for instance in food processing, but also in the production of car tyres. Lignin chemistry will be able to produce many of these compounds. And many more, like cross-linkers that can be added to polymers for property enhancement, and new fire retardants and resins.

‘Now the demand from the retail sector for low products with a low health impact is strongly increasing. In particular with regards to laminates and chipboard panels. So far, the gluing agents used in the pressing process, particularly for indoor qualities, slowly release formaldehyde. Phenolic resins are used in other qualities. Both formaldehyde and phenol are suspect for their health effects. Major furniture retailers are looking for alternatives to these products. Lignin and its decomposition products offer many opportunities in this field. Lignin already fulfils this function in wood, the feedstock. And substances derived from furfural (produced from agricultural side streams) can be substitutes for phenolic compounds. End users are looking dearly for the market introduction of such compounds in appreciable quantities. A similar route is softwood preservation by treating it with a resin, lending it a quality or robustness comparable to hardwood. Tropical hardwood has an appreciable ecological footprint, whereas pinewood for instance does not cause major ecological problems.’

Better lignin quality

Would it matter much if paper and pulp industries would produce a better lignin quality as their side streams? ‘Sulphur content of lignin from the paper and pulp industry is indeed a problem, as sulphur is an anticatalyst to processing reactions. Fortunately, many other lignin qualities come to the market now. Vito is also involved in a major European research project led by Finnish research centre VTT, devoted to the development of lignin from the paper industry to a valuable feedstock. This would be a major breakthrough, because a very large amount of feedstock would become available if this were successful. Another source of good lignin would be the side stream of second generation bioethanol production. Much too good to incinerate.’

‘However, the application of such products in chemical industry is hampered by a customary rule that energy production from side products counts as reduction of the CO2 footprint, whereas chemical applications do not. And for promotion of bioethanol the producers need to be able to claim as low a CO2 footprint as possible. For instance, bagasse, a lignin containing side product of sugar production, is used in great quantities for production of process heat. For this heat production, zero CO2 emission is accounted for; the same emission would result from processing this feedstock to chemical products and materials – but accounting rules have not been based on that fact. In the long run, this will end only if and when bagasse itself becomes a valuable commodity.’ I.e. if second generation ethanol would make a breakthrough, and if there would be a simultaneous demand for lignin for the above-mentioned applications.

New processes

‘We plan to treat the wood feedstock directly, catalytically, in order to produce lignin derivatives. This is a process developed by Leuven Catholic University, and Vito does the membrane separation. This is exactly the opposite of the classical pulp & paper process. In our new process, cellulose and (partly) hemicellulose precipitate in the form of pulp, whereas lignin breaks down to monomers. The interesting thing is that this can be done in existing chemical reactors – a factor that prevents the need of major investment costs, at least in the short term. I feel that lignin is a feedstock with a great potential. We have just started to scratch the surface.’ Says Ludo Diels.

Interesting? Then also read:

Wood biorefinery has an enormous potential

Isosorbide, a biobased molecule with a bright future

Biobased building blocks: an update